|

|||||||

Post Reply |

|

|

Thread Tools | Search this Thread |

| 07-09-2013, 02:46 AM | #199 | |||

|

Major General

1712

Rep 5,109

Posts |

Quote:

Which was written on an iPhone and was therefor very short without all the possible "if's and but's"... My statement as regards the videos should obviously have been more precise for you. It sounds more similar to the Ferrari than the Mustang does. It doesn't sound the same. It sounds more similar just as any engine would at revs approaching the 458's redline. My son has a Focus with a 2l engine with a redline at 7400rpm, that engine sounds more like the Ferrari than a 2l with 6000rpm redline. But no one would mistake it for a Ferrari... Even though in reality a highly tuned NA 4 cylinder at 9000rpm sounds more like it because of the same crank design and firing order. I'll try to restate my point in the simplest way possible. A straight piped S65 and a P65 sounds different BECAUSE of the crankshaft. Take any V8, change to a flat plane crankshaft and the engine will sound very differently. I'm not talking about how different exhaust sytems, intake systems etc. can change the sound. Because those are added on parts that can be changed on any car. Yes, of course the exhaust system is vitally important to the sound level. But, just as you can put a straight pipe system on a M3, so can you on a Mustang etc... That changes the sound pressure (noise level), but won't get rid of the V8 burble that is due to the two adjacent cylinders firing in a row on the same bank. You would never say that a 4 cyl engine sounds like a cross plane V8 would you? Notice that the flat plane crank V8 actually is a two 4 cyl engines coupled together with the same firing order as a 4 cyl engine (for each bank)? This makes a flat plane crank V8 sound very differently to a cross plane engine, and perahps even a little bit uninspiring at idle (since it sounds more similar to a 4 cyl engine at idle). Quote:

The NVH issues are probably the main reason BMW didn't go that route. Quote:

What have been my points is: A flat plane crank V8 engine makes a different sound than a cross plane engine A flat plane V8 has better exhaust scavenging (due to more ideal firing order) A flat plane V8 has a lighter crankshaft, meaning sharper response A flat plane V8 is preferred for high rpms and power (and often come in cars where NVH issues are expected and accepted by the owners) I have not claimed that it's impossible to make a high performance cross plane V8, just as it's also possible to make a low performance flat plane V8 (if someone should be stupid enough to pursue such a option)  Yes, you can make a high performance cross plane V8 (just look at the S65 and NASCAR), and I have never claimed otherwise. The hardware needed to do that is the same hardware needed to make high performance on a flat plane crank V8. So, in that respect the S65 (or any other high performance NA engine) is more similar to a Ferrari engine than it is to a plain Jane V8. Just as a Ford Racing 5.0L Aluminator engine also is more similar with 100hp/l: http://fordracingparts.com/parts/par...KeyField=23300 Which again leves us with one major difference, the crankshaft layout. And, that is more important than just creating a different sound. It gives the engine sharper response and better exhaust scavenging. Meaning it's easier to achieve more power as the exhaust scavenges the cylinders better. Which then can either give you more power with similar cam timing, or less aggressive cam timing and same hp. Both layouts have their pros and cons, but for uncompromised power, the flat plane is preferred. Back to forced induction  Last edited by Boss330; 07-09-2013 at 12:29 PM.. |

|||

|

Appreciate

0

|

| 07-09-2013, 09:07 AM | #201 | |

|

Moderator

7509

Rep 19,370

Posts |

Quote:

|

|

|

Appreciate

0

|

| 07-09-2013, 12:14 PM | #202 |

|

Second Lieutenant

2

Rep 220

Posts |

So we can wait lag free engine, whit turbo-, kompressor charger, thing which eliminate lag and power rising until limiter is reached. Interesting, will it reaction even faster than NA engine...

|

|

Appreciate

0

|

| 07-09-2013, 02:30 PM | #203 | |

|

Major General

1712

Rep 5,109

Posts |

Quote:

One of the reasons a turbo engine won't have as instantaneous throttle response as a NA engine is that it takes time to build boost pressure and that the total "intake volume" that the turbo has to pressurize is much larger than on a NA engine (tubing to and from the intercooler, the intercooler). Even with the new electrically driven turbos, as seen on next years F1 engines, it will still take time to build pressure. But, the beauty of the electically driven turbo is that it can respond instantaneously to throttle input. Ie, the moment you depress the throttle, the electric motor can immediately start spooling up the turbo and build boost pressure before the exhaust has time to start the spooling up process. In theory you could also have a "M-mode" with a anti lag function where the electric motor spins the turbo to maintain boost pressure, regardless of throttle position and/or exhaust flow. Similar to what WRC cars does. These boost around 1bar at idle I believe. In that scenario you would allways have a certain minimum of boost available, even when coasting or sitting at a red light at idle. That would create a allmost lag free engine. In reality with negligible lag. Just imagine the torque and hp curve of such a engine  If BMW does this, or something similarly new tech, we will again have a classic M engine I believe. |

|

|

Appreciate

0

|

| 07-09-2013, 02:40 PM | #204 |

|

Major General

5457

Rep 7,037

Posts |

You shouldn't neccesarily need to drive the turbos to always keep the intake system pressurized. You would think a more simple electrical pump and some valves that switches when the turbos are up to speed would suffice. This to me this seems simpler and cheaper than electrically driving the turbos or an engine belt driven kompressor solution.

|

|

Appreciate

0

|

| 07-09-2013, 03:06 PM | #205 | |

|

Major General

3487

Rep 9,709

Posts |

Quote:

You bang on about the superiority of the s65. I mentioned the older s54, that, yes has older ECU technology, older VANOS technology, older everything, yet is superior in maximum torque per litre, and about equal on horsepower per litre as the newer S65. If s54 had all the s65 upgrades it would be even closer on power output, despite being 19% down on displacement. That means it is a superior engine in my book. You bang on about the superiority of the s65. I mentioned the older s54, that, yes has older ECU technology, older VANOS technology, older everything, yet is superior in maximum torque per litre, and about equal on horsepower per litre as the newer S65. If s54 had all the s65 upgrades it would be even closer on power output, despite being 19% down on displacement. That means it is a superior engine in my book.  |

|

|

Appreciate

0

|

| 07-09-2013, 04:00 PM | #206 | |

|

Major General

3487

Rep 9,709

Posts |

Quote:

To me NA on track is boring, what others describe as instant throttle response to me is a difference in engine note, but no major action, no white knuckles, no sweaty brow, no hairs standing up on the neck, no 100 yard of black stripes out of that slow corner. Maybe I need to drive a Zonda to feel this excitement? I don't have Zonda money. The beauty of the turbo.  Turbo lag? a non issue if you know what you're doing  |

|

|

Appreciate

0

|

| 07-09-2013, 04:08 PM | #207 | |

|

Major General

1712

Rep 5,109

Posts |

Quote:

It needs to flow enough air to support the engine's airflow capacity/usage at low to at least medium rpm. Remember, the intake of a engine isn't a closed chamber that you just can pressurize without pumping large volumes of air into. You would need a VERY large volume pump to feed the engine enough air and at the same time pressurize the intake system... A 3l engine pumps between 5-6.000 liters of air at 4000rpm... What your solution basically would need was an extra air pump, with all the extra valves and weight plus complexity, when you simply can bolt on a electric motor/generator on the turbo and get double use of the turbo (both as a exhaust driven air pump and as a electrically driven air pump) instead of having the complexity of even one more large air pump... Not to mention that the electric motor/generator also can act as a boost controller, getting rid of the wastegate. And regenerate exhaust energy when it slows the turbo down (or brakes the turbo to maintain a certain boost pressure at full throttle). Your extra air pump would need a really powerful electric engine to be able to support enough air. That would be worse for fuel economy (alternator needs to charge the battery more) and add weight. A turbo with a motor/generator both takes use of the allready existing air pump (the turbo) and can regenerate electricity as explained above. And it get's rid of the wastegate. Last edited by Boss330; 07-09-2013 at 04:25 PM.. |

|

|

Appreciate

0

|

| 07-09-2013, 04:12 PM | #208 | |

|

Major General

3487

Rep 9,709

Posts |

Quote:

|

|

|

Appreciate

0

|

| 07-09-2013, 04:23 PM | #209 |

|

Major General

5457

Rep 7,037

Posts |

A turbo is a design optimized to be driven by exhaust not an electrical engine. It requires very high rpm to produce useful boost. You would think that a pump/kompressor optimized to be driven by an electrical power source would easily be much more energy efficient?

To keep a turbo always spinning seems to be even more wasteful since it needs to be working constantly off boost. A pump would just need to keep pressure up. It's obviously a lot more to it but the concept of using a device optimized to be driven electrically than driving a device optimized to be driven as a turbine by exhausts seems reasonable to me. The electrical power source could be a generator hooked up to the turbos to take advantage of surplus energy generated by the turbos with battery backup. A KERS like system with charge and discharge operation should suffice if the intake system uses a clever valve system to keep pressure between charges. Maybe...just speculating here  Last edited by solstice; 07-09-2013 at 04:32 PM.. |

|

Appreciate

0

|

| 07-09-2013, 04:32 PM | #210 | |||

|

Major General

1712

Rep 5,109

Posts |

Quote:

And if you allready plan on attaching a generator to the turbo... Then you allready have your electrical motor mounted to the turbo... Why not take advantage of it??? Like F1 engines does next year... And probably why BMW has patented their electric turbo design: http://f80.bimmerpost.com/forums/sho...d.php?t=597327  Of particular interest is the MGU-H (Motor Generator Unit - Heat) that is attached to the turbo: Quote:

Quote:

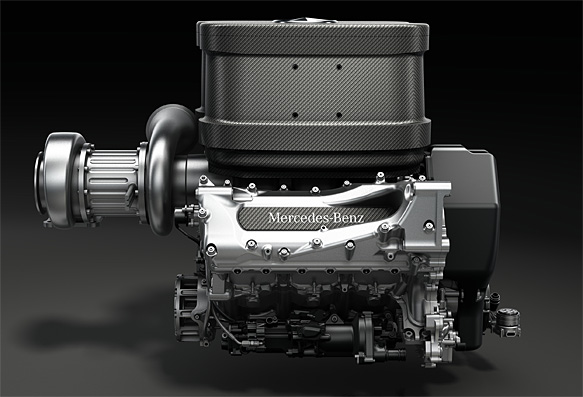

Any rumours of a electric turbocharger on the next M3/M4 might be a similar device as shown here, to spool up the turbos, or slow it down instead of using a wastegate to dump excess exhaust. Source: http://www.renaultsport.com/Nouvelle...Energy-F1.html Here is MagnetiMarelli's version of a "electric/hybrid" turbo. TThey have chosen a slightly different solution with the generator/motor unit between the compressor and turbine units of the turbo. Seems like Mercedes is using a variant of this solution as well.   BTW, this is what next years F1 engine will sound like: |

|||

|

Appreciate

0

|

| 07-09-2013, 04:44 PM | #211 |

|

Major General

5457

Rep 7,037

Posts |

I understand what they are doing and I suspect they have investigated it but I'm not in anyway or form convinced that driving a turbine optimized for exhaust sourced energy is the most efficient use of the electrical energy you have access to.

Do you think it makes sense from a scientific/engineering aspect that an exhaust driven turbine just happen to be optimal to also be driven by an electrical device? You should be able to separate energy generation and the use of it. I.e independent of what boost device you use, you can use the same device for re-generation. Do I think I know better than Renault's and BMW engine cream of the crop engineers? No, but from a pure scientific aspect there are question marks of efficiency. I think you misunderstood my "off boost", I meant when the turbos are below minimum boost, I.e both to keep the system pressurized when the intake is closed and keep a constant flow of the same boost from opening until the turbos spins up and take over. Last edited by solstice; 07-09-2013 at 04:54 PM.. |

|

Appreciate

0

|

| 07-09-2013, 04:51 PM | #212 | |

|

Major General

3487

Rep 9,709

Posts |

Quote:

|

|

|

Appreciate

0

|

| 07-09-2013, 05:05 PM | #213 | |

|

Major General

5457

Rep 7,037

Posts |

Quote:

Last edited by solstice; 07-09-2013 at 05:11 PM.. |

|

|

Appreciate

0

|

| 07-09-2013, 05:42 PM | #214 | |

|

Banned

205

Rep 7,298

Posts |

Quote:

And I think you just slipped and admitted that there is turbo lag in your last sentence  And interesting picture in your sig....is that a turbo m3 that you so admire? (i hope its not so i dont shoot myself in the foot! haha) |

|

|

Appreciate

0

|

| 07-09-2013, 07:03 PM | #215 | |

|

Lieutenant General

609

Rep 10,407

Posts |

Quote:

The problem is that judging and engine only by specific output is simply not capturing everything that matters in an engine. Peak hp is far more important in a practical sense, i.e. who cares is your super tech, super tuned 2.0l tubro has 200 hp/l. It will still get tromped by a 500 hp low tech engine (if the cars weight about the same). Engines tend to defy the single metric of classification or ranking. For me the two most important again from a very practical sense are peak hp and torque curve (I could just as well say the entire hp curve but as you know it is easier to visually inspect a torque curve since the ups and downs are hidden a bit by rpm at higher rpm). I also like the experience and benefits of high redlines but that is more about engine character than a totally real world concern. From a purely engineering/technical point of view, specific output might be the best single simple metric. As a counter example some of the recent Corvette engines come to mind. Relatively low tech, push rods, not great specific power nor specific torque but big torque, big power, reliable and even great fuel efficiency (in some cases when combined with tricky auto short shifting).

__________________

E92 M3 | Space Gray on Fox Red | M-DCT | CF Roof | RAC RG63 Wheels | Brembo 380mm BBK | | Vorsteiner Ti Exhaust | Matte Black Grilles/Side Gills/Rear Emblem/Mirrors | | Alekshop Back up Camera | GP Thunders | BMW Aluminum Pedals | Elite Angels | | XPEL Full Front Wrap | Hardwired V1 | Interior Xenon Light Kit | |

|

|

Appreciate

0

|

| 07-09-2013, 07:48 PM | #216 | |

|

BMW Fan

449

Rep 725

Posts |

Quote:

Ive driven a 590whp/540wtq NA 454 LS7 in a C5 Z06 and it had more than enough power to give you throttle response with white knuckles. I've seen a few 500ci LS engines out there as well. No need to drive a Zonda. There are cheaper alternatives.  |

|

|

Appreciate

0

|

| 07-09-2013, 09:36 PM | #218 | |

|

General

21115

Rep 20,741

Posts

Drives: 2021 911 turbo

Join Date: Jan 2012

Location: Montreal

|

Quote:

This is exactly what I am hoping for. This is exactly what I am hoping for. |

|

|

Appreciate

0

|

| 07-09-2013, 10:03 PM | #219 | |

|

General

21115

Rep 20,741

Posts

Drives: 2021 911 turbo

Join Date: Jan 2012

Location: Montreal

|

Quote:

The compressor is optimized to operate over a given running line (RPM and mass flow dependent). As long as the compressor runs in its optimal range, the efficiency is maintained regardless if the compressor is driven directly from the turbine or by an electric motor. The turbine does not need to be driven by an electric device. If the turbine, compressor and electric motor/generator can be selectively coupled and decoupled via clutches, the electric motor could only be driving the compressor without having to drive the turbine. This improves efficiency and the size of the required electric motor. Under full boost, the turbine is mechanically connected to the compressor. When the desired boost level is achieved, the electric motor/generator goes in "regen" mode and controls the turbine/compressor speed by braking it; thus eliminating the need for a waste gate. This is quite well explained in this thread (link already provided by Boss330) http://f80.bimmerpost.com/forums/sho...d.php?t=597327 However, contrary to what this thread explains, I believe that the electric motor could actually be used to maintain boost (the M mode Boss330 is alluding to) and not just using the motor inertia to accelerate the compressor when needed . When the throttles are closed, not that much mass flow needs to be supplied to maintain boost. The electric motor could be powerful enough to maintain the boost level and even further reduce (if not eliminate) the lag. I also believe Boss330 is correct, sufficient mass flow needs to be supplied by the compressor to maintain boost, since the engine is still consuming air. A simple air pump would not be sufficient. Last edited by CanAutM3; 07-09-2013 at 11:25 PM.. |

|

|

Appreciate

0

|

| 07-09-2013, 10:15 PM | #220 |

|

Major General

5457

Rep 7,037

Posts |

CanAutoM3 , now that makes a lot more sense and is a variant of what I suggested. To drive the kompressor electrically would be much more efficient than to drive the turbines.

|

|

Appreciate

0

|

Post Reply |

| Bookmarks |

|

|