Quote:

Originally Posted by solstice

A turbo is a designed optimized to be driven by exhaust not an electrical engine. It requires very high rpm to produce useful boost. You would think that a pump/kompressor optimized to be driven by an electrical power source would easily be much energy efficient?

To keep a turbo always spinning seems to be even more wasteful since it needs to be working constantly off boost. A pump would just need to keep pressure up. It's obviously a lot more to it but the concept of using a device optimized to be driven electrically than driving a device optimized to be driven as a turbine by exhausts seems reasonable to me.

The electrical power source could be a generator hooked up to the turbos to take advantage of surplus energy generated by the turbos with battery backup.

|

It would not "just" need to keep the pressure up... It would also need to pump enough volume of air to feed the engine... And the idea to keep the turbo spinning isn't to have it "working off boost". You would want it spinning to

provide boost, that's the whole point...

And if you allready plan on attaching a generator to the turbo... Then you allready have your electrical motor mounted to the turbo... Why not take advantage of it???

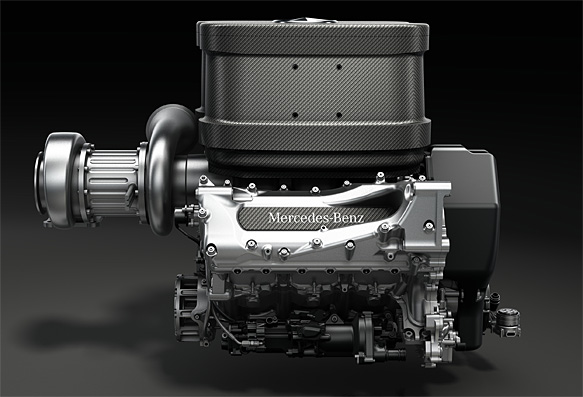

Like F1 engines does next year... And probably why BMW has patented their electric turbo design:

http://f80.bimmerpost.com/forums/sho...d.php?t=597327

Of particular interest is the MGU-H (Motor Generator Unit - Heat) that is attached to the turbo:

Quote:

TURBOCHARGER

A turbocharger uses an exhaust driven turbine to drive a compressor to increase the density of the intake air consumed by the engine and so make more power for a given displacement.

The residual heat energy contained in the exhaust gases after expansion in the cylinders of the engine is converted to mechanical shaft power by the exhaust turbine. The mechanical power from the turbine is used to drive the compressor, and also the MGU-H (see below).

As the turbocharger speed must vary to match the requirement of the engine, there may be a delay in torque response, often known as turbo-lag. One of the great challenges of the new Power Unit is to reduce this to near zero to match the instant torque delivery of the current V8 engines.

|

Quote:

MGU-H

The MGU-H is connected to the turbocharger. Acting as a generator, it absorbs power from the turbine shaft to recover heat energy from the exhaust gases. The electrical energy can be either directed to the MGU-K or to the battery for storage for later use. The MGU-H is also used to control the speed of the turbocharger to match the air requirement of the engine (eg to slow it down in place of a wastegate or to accelerate it to compensate for turbo-lag.)

|

This is a brilliant piece of engineering, possibly a game changer of power delivery characteristics on a turbocharged engine

Any rumours of a electric turbocharger on the next M3/M4 might be a similar device as shown here, to spool up the turbos, or slow it down instead of using a wastegate to dump excess exhaust.

Source:

http://www.renaultsport.com/Nouvelle...Energy-F1.html

Here is MagnetiMarelli's version of a "electric/hybrid" turbo. TThey have chosen a slightly different solution with the generator/motor unit between the compressor and turbine units of the turbo. Seems like Mercedes is using a variant of this solution as well.

BTW, this is what next years F1 engine will sound like: